Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

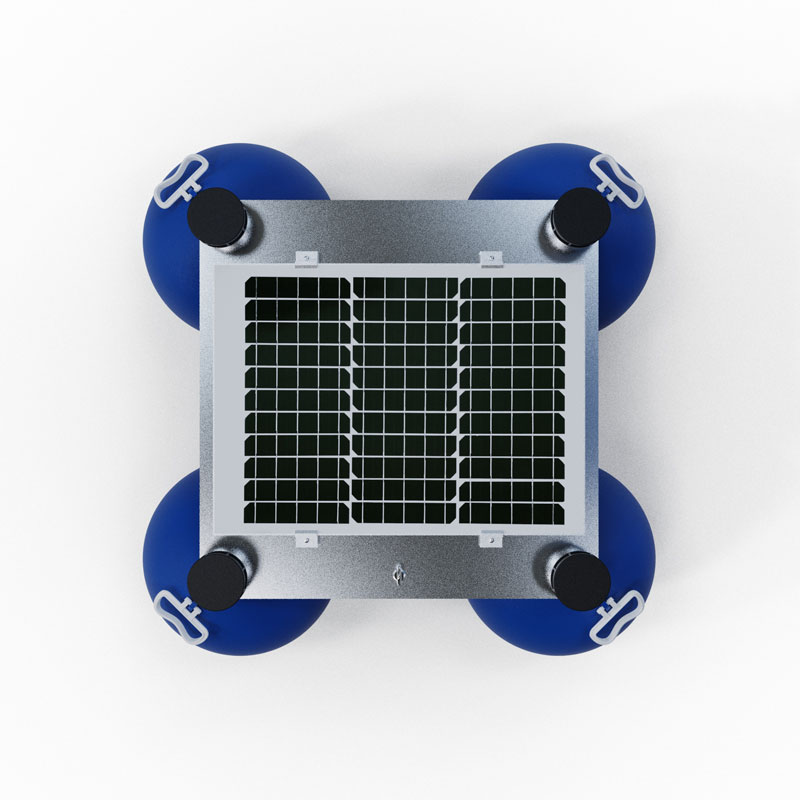

Model:FT-SFA

Brand:tianqiong

1.Introduction to Water Quality Monitoring Buoy Functions

Water Quality Monitoring Buoy is a small, rapidly deployable buoy used to monitor water quality in harbours, rivers and protected waters.

1.Water Quality Monitoring BuoySFA unattended acquisition system integrating data acquisition, storage, transmission and management.It is an automatic hydrological measurement and reporting system for industrial and agricultural production, tourism, urban environmental monitoring, geological disasters, flood control, water scheduling, power station and reservoir water situation management, etc.; the powerful upper computer software can remotely observe real-time water and rain information, and has database, reports, download and other functions.Users can also use this complete meteorological software to further process and analyze the recorded data.

2.The water quality monitoring system consists of six parts: water quality sensor, data collector, communication system, power supply system, overall support, and water quality monitoring platform.It can simultaneously monitor water temperature, pH, dissolved oxygen, conductivity, ammonia nitrogen, turbidity, COD, etc., and a variety of water quality factors.The data collector has data acquisition, real-time clock, data timing storage, parameter setting and standard 2G/4G (GPRS) communication functions.

2.Water Quality Monitoring Buoy product features

1.Easy to deploy: All types of probes are highly integrated and easy to install; free cloud platform services are provided, and the system is quickly launched;

2.Easy maintenance: After the equipment is installed, it can work by itself, without manual duty, and the normal operation of the equipment can be ensured through remote monitoring;

3.Easy to expand: All sensor probes use a unified communication protocol, which can quickly connect to the original equipment and quickly expand monitoring parameters;

4.Low power consumption: The device can operate for a long time in a low power consumption state, increasing the convenience of the device;

5.Real-time: The data monitored by the device is transmitted to the cloud platform in real time, improving the timeliness of environmental data feedback.

3.Water Quality Monitoring Buoy Technical Parameters

1.Main parameters

| Product Name | describe |

| Water Quality Monitoring Buoy |

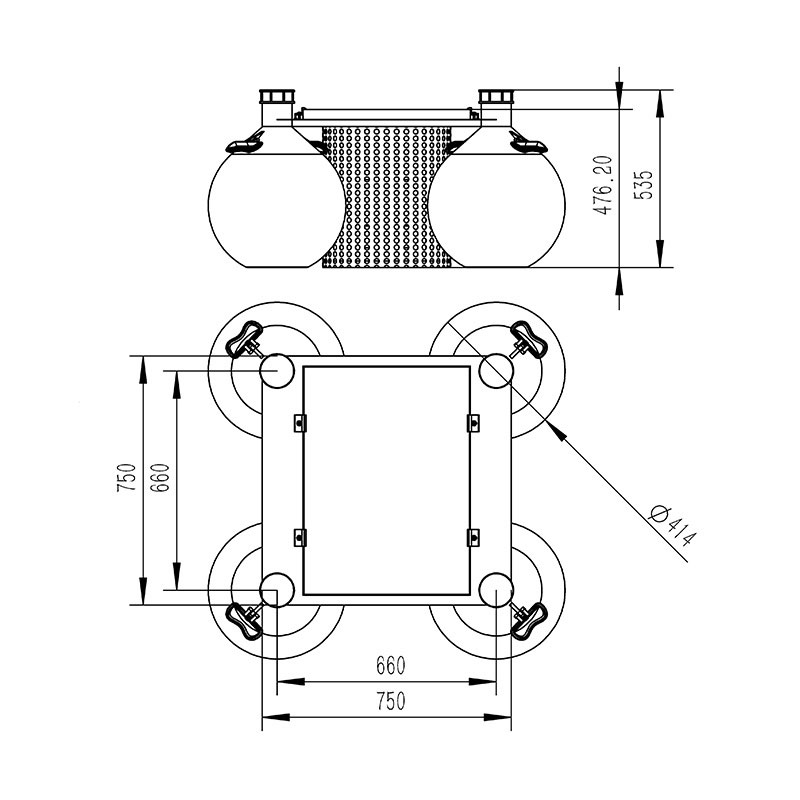

Online monitoring of multiple parameters can be realized in real time. Battery power monitoring can be realized. It can realize cloud platform data monitoring, data push, data storage and alarm functions; data wireless transmission functions. The peak power consumption is 5W; the sensor power consumption is about 0.25W per piece. Dimensions: 750mm*750mm*535mm.Float diameter 414mm Weight: 22kg |

| Collector data acquisition | Reliable operation, anti-interference, and can integrate multiple RS485/MODBUS-RTU slave equipment |

| Collector data output | 1-channel Rs485/JSON protocol output |

| Battery | Lithium battery 12VDC, 20AH (default) |

| Solar panels | 22.1V/50W (default) |

| Power supply capacity | Customized selection; work for more than 5 days during rainy days |

| Position indication (optional) | Warning light; GPS positioning; |

| Monitoring platform | Cloud platform; mobile phone/computer multi-terminal login |

| Protective cover | 304 stainless steel filter cartridge protective cover |

| Floating body | Diameter 414mm, spherical floating body * 4 engineering plastic |

2.The main parameters of optional sensors

| Model | Name | Measurement range | Principle | Measurement accuracy | Resolution | Is it standard equipment | Note |

| S1S | cod | 0~1000mg/L | UV254 absorption method | ±5%, ±0.3℃ | 0.1mg/L | cod turbidity integrated; brush self-cleaning, with temperature compensation | |

| Turbidity | 0~400NTU | Scattering light method | ±1%, ±0.3℃ | 0.1NTU | |||

| S2 | Water hardness | 0~1000.0mg/L | Contact method of electrode | Reading ±10%; ±0.3℃ | 0.1mg/L | ||

| S3 | pH | 0~14 (ph) | Electrochemistry (salt bridge) | ±0.1PH;±0.1℃ | 0.01 | With warm supplement | |

| pH | 0~14 (ph) | Electrochemistry (salt bridge) | ±0.1PH;±0.1℃ | 0.01 | |||

| S5 | Ammonium nitrogen | 0~1000mg/l | Ion selective electrode method | 10% of the reading, ±0.5℃ | 0.01mg | Ammonia nitrogen pH integrated; with temperature compensation | |

| pH | 0~14 (ph) | Electrochemistry (salt bridge) | ±0.1PH;±0.1℃ | 0.01 | |||

| S6 | ORP | -1500mv~1500mv | Electrochemistry (salt bridge) | ±6mv | 1mV | ||

| S7 | Electrical conductivity | 0~10000uS/cm | Contact method of electrode | ±1.5%; ±0.1°C | 1uS/cm | With warm supplement | |

| S7H | High range conductivity | 0~30000μS/cm | Contact method of electrode | ±1.5%; ±0.1°C | 1uS/cm | High range conductivity TDS salinity sensor; with temperature compensation | |

| TDS | 0-10000ppm | Contact method of electrode | ±1.5%; ±0.1°C | 1ppm | |||

| Salinity | 0-10000ppm | Contact method of electrode | ±1.5%; ±0.1°C | 1ppm | |||

| S8 | Dissolved oxygen | 0~20mg/L | Fluorescence lifetime method | ±2%, ±0.3℃ | 0.01mg/L | With warm supplement | |

| S9 | Turbidity | 0~1000NTU | Scattering light method | ±1%, ±0.3℃ | 0.1NTU | With warm supplement | |

| S10 | Suspended matter | 0~2000mg/L | Scattering light method | ±5% (depending on the homogeneity of the sludge) | 0.1mg/L | ||

| S11S | Sludge concentration | 0~20.000g/L | Scattering light method | ±5% (depending on the homogeneity of the sludge) | 0.001g/L | Brushed self-cleaning | |

| S15S | Chlorophyll | 0~400ug/L | Fluorescence method | R²>0.999 | 0.01ug/L | Self-cleaning with brush; with temperature compensation | |

| S16S | Cyanobacteria | 0~200.0Kcells/mL | Fluorescence method | R²>0.999 | 0.1Kcells/mL | Brushed self-cleaning | |

| S17S | Oil in water | 0~60ppm | Fluorescence method | 0.1ppm | 0.01ppm | Brushed self-cleaning | |

| S20 | Transparency | 50~1000mm | Scattering light method | ±5% (depending on the homogeneity of the sludge) | 1mm | With warm supplement | |

| S21 | Water temperature | −20℃~85℃ | High-precision digital sensor | ±0.1℃ | 0.1℃ |

Appropriate testing solutions can be customized according to the actual situation of the customer and the technical indicators to be achieved.

Note: The sensor cannot be installed inverted or horizontally when installed, and should be installed at least 15 degrees above the angle of inclination.

The working environment of the above water quality sensor is 0-50℃, <0.3Mpa.

4.Water Quality Monitoring Buoy product size diagram

5.Water Quality Monitoring Buoy equipment installation requirements

1.Stay away from high-power radio transmitters

2.Stay away from high-voltage transmission lines and microwave radio transmission channels

3.Try to be close to the data transmission network

4.Stay away from strong electromagnetic interference

An ultrasonic weather station is a modern meteorological monitoring device designed based on the principles of ultrasonics. It measures atmospheric parameters to provide real-time and accurate weather data for environmental monitoring, agriculture, urban management, and other fields. Compared to tra...

The Atmospheric Visibility Sensor is a device that accurately acquires atmospheric visibility data.The working principle of the Atmospheric Visibility Sensor is based on the theory of light scattering. The instrument is equipped with a light source of a specific wavelength, mostly an infrared LED li...

Soil electrical conductivity (EC) is a critical indicator for measuring the content of soluble salts in soil, reflecting the total concentration of various ions in the soil solution or the ionic strength of water-soluble substances. When salts in the soil dissolve, they exist in ionic form—the high...

I. Core Hardware Configuration(I) Meteorological SensorsBasic Elements: Wind speed, wind direction, air temperature, humidity, atmospheric pressure, rainfall, and light intensity sensors should be equipped as basic standards. The accuracy of each sensor should meet national meteorological instrument...