Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-S7

Brand:tianqiong

one.Water conductivity sensor application environment description

Water conductivity sensor measures water conductivity in real time for use in water, chemicals, power plants, life sciences, pharmaceuticals, food and beverages.It is used for environmental water quality detection and various high/low ionic strength water sample testing, which can meet the requirements of most industrial/environmental applications for online conductivity measurement.

Signal output: RS485 (MODBUS-RTU).

Internal signal isolation technology has strong interference.

Good reproducibility, thermal stability, low drift, small size, fast response speed

Easy to install, simple, 3/4NPT pipe threads, easy to sink-in installation or install in pipes and tanks

Stable performance and long service life

IP68 waterproof standard

24*1.2 18*1.5*2 28*2 2

two.Water conductivity sensor technical performance and specifications

1.Water conductivity sensor technical parameters

| Measurement principle | Contact electrode method |

| Signal method | RS485 (MODBUS-RTU) |

| Measurement range | 0~10000uS/cm |

| Measure resolution | 1 |

| Measurement accuracy | ±1.5%; ±0.1°C |

| Response time | About 30s (98% static liquid) |

| Housing material | ABS and 316L stainless steel |

| Temperature compensation | Automatic temperature compensation (M1820Z) |

| Cable length | Standard 5 meters |

| Power supply voltage | 12-24VDC (0.4W@12V) |

| Measurement environment | Temperature 0~50℃ (no freezing), <0.2MPa |

| Waterproof grade | IP68 |

| Installation method | Immersive mounting, NPT3/4 thread |

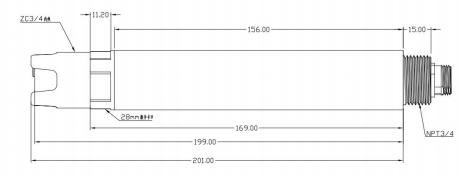

2.Water conductivity sensor size diagram

The sensor connector is M12 aviation plug connector 5-core mother seat

three.Water conductivity sensor installation and electrical connection

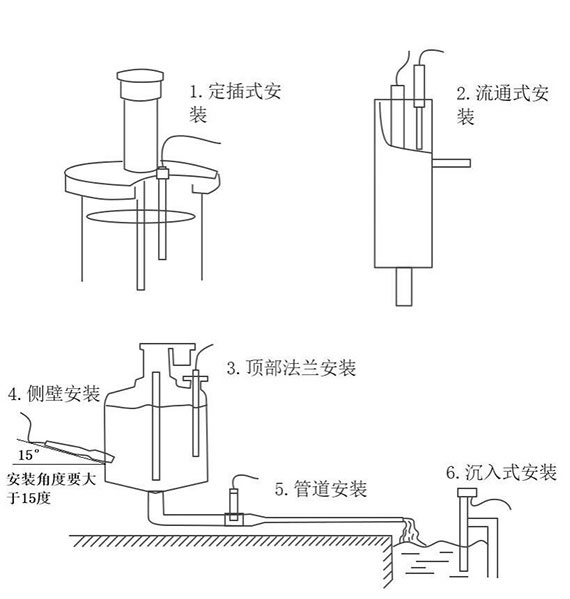

1.Water conductivity sensor installation

Note: The sensor cannot be installed inverted or horizontally when installed, and should be installed at least 15 degrees above the angle of inclination.

2.Water conductivity sensor electrical installation

The cable is a 5-core shielded wire, line sequence definition: brown-power cord (12~24VDC)

Black-ground (GND)

Blue-485A Green-485B

Yellow - 4-20mA current output (can be suspended if not used)

Before powering on, carefully check the wiring sequence to avoid unnecessary losses caused by wiring errors.

Four.Water conductivity sensor maintenance and maintenance

1.Use and maintain

Conventional electrodes require periodic cleaning and calibration, and the maintenance cycle is determined by the customer according to their working conditions.Conventional electrode cleaning methods: Use a soft brush to remove attachments (be careful to avoid scratching the electrode surface), then clean with distilled water, and then perform calibration operations.

In the context of the increasingly accelerating urbanization process today, air quality has become one of the key elements for measuring the quality of life. However, due to the high construction and operation costs and fixed layout, traditional large-scale environmental monitoring stations find it...

The construction of smart wetlands takes wetland monitoring equipment as the core, and combines Internet of Things (IoT), big data, and artificial intelligence technologies to build a three-dimensional monitoring network covering hydrology, meteorology, and ecology.The wetland weather stations...

Portable Weather Station is a highly integrated, low-power, and rapidly deployable high-precision automatic meteorological observation device. It is suitable for various scenarios such as emergency short-term meteorological observation, mobile meteorological monitoring, and microclimate environment monitoring. It is primarily used for data acquisition in fields such as meteorology, agriculture and forestry, environmental protection, and emergency monitoring....

Negative Oxygen Ion Monitoring Station FT-FZ1 is an environmental monitoring device used to measure and display the concentration of negative oxygen ions in the air.The function of FT-FZ1 is to automatically monitor the concentration of negative oxygen ions in the air around the clock. Negative oxyg...