Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Model:FT-S18S

Brand:tianqiong

1.Biochemical oxygen demand sensor Working Principle

Biochemical oxygen demand sensor uses optical measurement principles to monitor the biological oxygen demand in water bodies in real time and accurately.Biochemical oxygen demand sensor employs a dual-light source for measurement: one for COD and one for turbidity.

Because dissolved organic matter in water absorbs ultraviolet light, the COD value can be measured by the transmittance of the light source. The turbidity measurement function automatically compensates for turbidity. Simultaneously, temperature is collected for temperature compensation. The BOD value is calculated from the COD value.

2.Biochemical oxygen demand sensor Technical parameters

| Measurement principle | UV254 absorption method Dual-source measurement |

| COD range | Default 0 to 1000 mg/L |

| BOD range | Default 0 to 400 mg/L |

| Resolution | 0.1mg/L |

| Precision | ±5%, ±0.3℃ |

| NTU Range | Default 0-400NTU |

| Resolution | 0.1NTU |

| Temperature compensation | Automatic temperature compensation |

| Self-cleaning function | Equipped with an automatic cleaner to prevent biofouling and light window contamination, ensuring stable long-term monitoring; the automatic cleaning time and frequency can be set, with a power consumption of 0.7W. |

| Output method | RS-485 (Modbus/RTU) |

| Storage temperature | -5-+65℃ |

| Work environment | 0~50℃,≤0.2MPa |

| Installation method | Immersion mounting, 3/4 NPT mounting thread |

| Cable length | 5m |

| Power supply | DC: 12V-24V |

| Protection level | IP68 |

| Calibration method | Two-point calibration |

| Case material | ABS+316L stainless steel |

3.Biochemical oxygen demand sensor Size/Installation

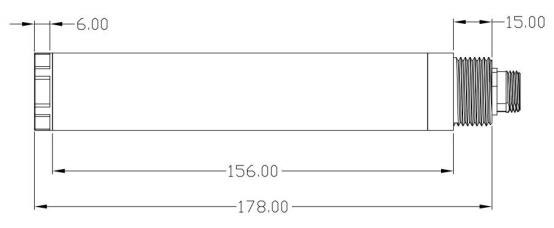

1.Biochemical oxygen demand sensor Dimensions

2.Biochemical oxygen demand sensor Wiring Diagram

The cable is a 5-core shielded cable:

Red wire—Power wire; Black wire—Ground wire; Green wire—485A; White wire—485B

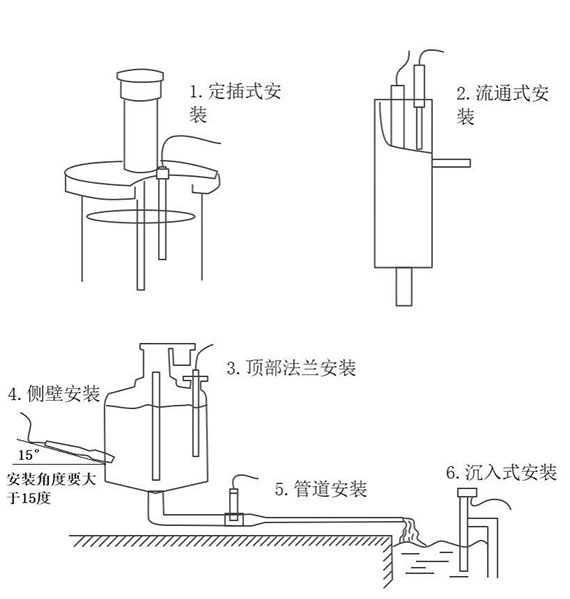

3. Biochemical oxygen demand sensor Installation

Note: The sensor must not be installed upside down; it should be installed at an angle of at least 15 degrees.

4.Biochemical oxygen demand sensor Maintenance and Care

Sensor Maintenance:

If the sensor needs cleaning, use warm water and a suitable amount of detergent.

Caution:

Avoid strong vibrations that could damage the front transparent glass. Do not scratch it with hard objects.

5.Biochemical oxygen demand sensor User Calibration

The sensor undergoes rigorous calibration at the factory and generally does not require user calibration. If user calibration was performed, the factory reset command can be executed to restore it.

5.1 Zero-Point Calibration

Immerse the sensor in a container using distilled or purified water. After 30 seconds of stable readings, perform turbidity and COD zero-point calibrations according to the communication commands.

5.2 Slope Calibration

Immerse the sensor in a solution container with a known turbidity value. After 30 seconds of stable readings, perform turbidity slope calibration according to the communication commands.

Immerse the sensor in a solution container with a known COD value. After 30 seconds of stable readings, perform COD slope calibration according to the communication commands.

Soil electrical conductivity (EC) is a critical indicator for measuring the content of soluble salts in soil, reflecting the total concentration of various ions in the soil solution or the ionic strength of water-soluble substances. When salts in the soil dissolve, they exist in ionic form—the high...

In the water conservancy and water services industry, water regime monitoring is a fundamental task. Especially during summer when natural disasters occur frequently, monitoring enables disaster prediction and provides data support for formulating flood prevention and relief plans. With the applicat...

When traditional mechanical weather stations monitor wind speed and direction, they encounter a difficult problem. The wind speed sensor usually consists of wind cups and an axis, and the wind direction sensor relies on mechanical components such as a wind vane. When these mechanical components are...

In modern traffic management, real-time and accurate road condition monitoring is of great significance for ensuring driving safety and improving road operation efficiency. Traditional road weather stations typically require embedded installation, which not only damages the road structure but may al...