Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-05-08 09:55:56 source:Weather Station viewed:240 time

In the photovoltaic industry, the problem of black edges on photovoltaic modules is quite common. The black edges are mainly caused by poor sealing of the frame during the module encapsulation process, which allows water vapor and oxygen to penetrate, causing oxidation or corrosion at the edges of the cells. It can also be due to insecure soldering of the ribbon in the production process, resulting in uneven current distribution at the edges, causing local overheating and leading to a decline in the performance of the cells, ultimately forming black edges. The black edges not only affect the appearance of the modules but also reduce the power generation efficiency and shorten the service life of the modules.

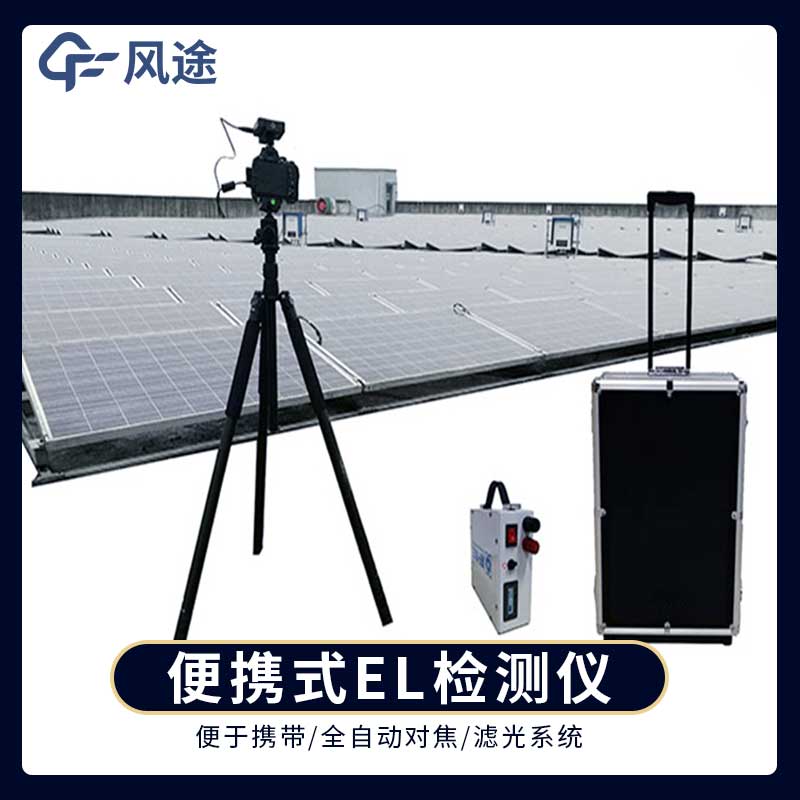

To ensure the quality and power generation efficiency of photovoltaic modules, comprehensive inspection work is crucial. The el detector (Electroluminescence Tester) is an important inspection tool. Based on the principle of electroluminescence, it applies a forward bias voltage to the photovoltaic module, causing electrons and holes inside the cells to recombine and release photons. Then, a high-sensitivity camera is used to capture these photons, generating images of internal defects in the module, thus intuitively presenting the internal condition of the module.

The el detector can not only detect the problem of black edges but also accurately identify a variety of potential defects. For example, hidden cracks are generated due to mechanical stress during transportation, installation, or use, which will reduce the strength and conversion efficiency of the cells. Broken pieces and fragments are formed by the fracture of the cells, affecting the overall performance and reliability of the module. Broken grids mean that the electrode grid lines of the cells are broken, resulting in poor current collection and reducing the power generation efficiency. "Black hearts" are mostly caused by internal defects or damage to the cells, also affecting the power generation capacity. Insecure soldering makes the connection between the cells and the ribbon unreliable, causing poor contact and interruption of current transmission. Hot spots are local overheating phenomena caused by uneven shading or aging of the cells, which can damage the module when severe.

In addition, the el detector can also detect problems such as process pollution, low-efficiency cells, sintering, over-etching, perforation, and PID. Process pollution will change the characteristics of the cells, and low-efficiency cells will reduce the overall performance of the module. Sintering, over-etching, and perforation affect the structural integrity of the cells, and PID will cause a rapid decline in the performance of the module.

In conclusion, the el detector is a key tool for the quality inspection of photovoltaic modules. It can comprehensively and accurately identify problems, providing strong support for the quality control and reliable operation of photovoltaic modules and promoting the healthy and stable development of the photovoltaic power generation industry.

In the production and use of photovoltaic modules, grid breakage is a relatively common and thorny problem. Grid breakage refers to the existence of breakpoints in the silver paste printing of the main grid of the solar cell, which causes the fine grid lines on the solar cell to be open-circuited wi...

An ultrasonic weather station is a modern meteorological monitoring device designed based on the principles of ultrasonics. It measures atmospheric parameters to provide real-time and accurate weather data for environmental monitoring, agriculture, urban management, and other fields. Compared to tra...

Faced with numerous types of anemometers on the market, how can one select a product that meets their own needs? First, let's understand the common types of anemometers.Mechanical AnemometerAmong mechanical anemometers, the cup anemometer is relatively common. It relies on the rotation of cups u...

In modern traffic management, real-time and accurate road condition monitoring is of great significance for ensuring driving safety and improving road operation efficiency. Traditional road weather stations typically require embedded installation, which not only damages the road structure but may al...