Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-09-24 09:10:17 source:Weather Station viewed:255 time

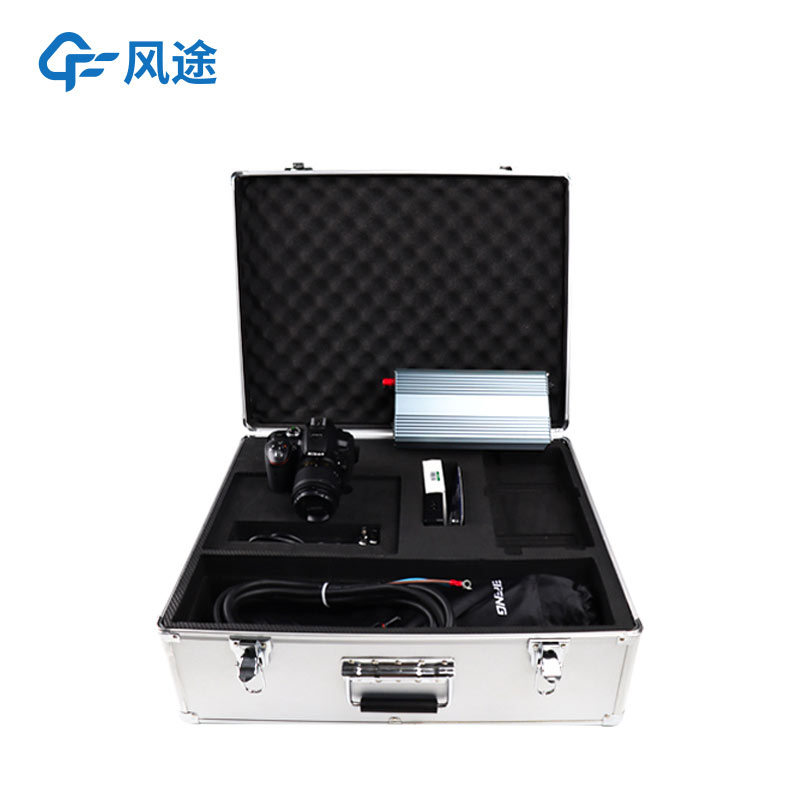

Many critical defects in solar cells, such as tiny microcracks, are completely hidden inside the cells and cannot be detected by the naked eye or even ordinary cameras. These defects can seriously affect the power generation efficiency and lifespan of the modules. Therefore, EL (Electroluminescence) camera detectors are deployed to ensure component quality control.

The working principle of an EL detector is based on the electroluminescence effect. Simply put, it reverses the operation of a solar cell: when a forward bias voltage is applied to the photovoltaic module and current is injected, electrons inside the cell undergo energy level transitions, thereby releasing photons mainly in the near-infrared spectrum (wavelength approximately 1000-1100 nanometers). In defective areas, the resistance is higher or recombination is stronger, resulting in weaker light emission. After a high-sensitivity infrared camera captures these light differences, on the image, normal areas appear bright while defective areas appear as dark shadows, making internal defects clearly visible.

It can be said that EL detectors are used throughout the entire lifecycle of photovoltaic modules. They perform random inspections after key processes such as lamination and framing, promptly removing defective products and ensuring quality control from the source. During power station construction acceptance and regular maintenance, they are used to detect microcracks generated during transportation and installation of modules, or to identify issues such as hot spots and PID (Potential Induced Degradation) attenuation that cause reduced power generation, ensuring the safety and profitability of power stations.

Today, highly integrated and lightweight portable EL detectors have become the market mainstream, and can even be mounted on drones to achieve efficient inspection of large-scale photovoltaic power stations. Combined with artificial intelligence image recognition algorithms, they can automatically identify and classify defects and generate detailed inspection reports, greatly improving the objectivity and efficiency of detection.

Expressways, as the main arteries of transportation, are crucial for the movement of people and the transportation of goods. However, severe weather such as heavy rain, heavy snow, dense fog, and strong winds frequently disrupts the operation of expressways, posing challenges to traffic order and tr...

In tourist attractions, air quality is one of the important factors attracting visitors. As a key indicator for measuring air quality, negative oxygen ion concentration has received increasing attention from more and more scenic spots. Known as the "vitamin of the air," negative oxygen ion...

Vehicle-mounted anemometer and wind direction sensor is a meteorological monitoring device specifically designed for mobile platforms. It utilizes a two-element integrated ultrasonic sensor to provide real-time wind speed and direction measurements. Its top cover features a concealed probe des...

As environmental pollution becomes increasingly complex, the limitations of traditional air monitoring methods are gradually becoming apparent. The national ambient air monitoring network has a limited number of stations and high costs, and the method of using points to represent the whole area resu...