Tianqiong Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-10-10 09:17:33 source:Weather Station viewed:239 time

Due to the special nature of their production processes, chemical plants have strict requirements for meteorological condition monitoring. This need stems from two core backgrounds: first, from a safety perspective, many chemical materials are extremely sensitive to wind speed, wind direction, and other factors. Minor leaks can spread rapidly under specific meteorological conditions, triggering safety accidents; second, from an environmental protection and compliance perspective, regulations in various countries usually require chemical plants to continuously monitor meteorological conditions in and around the plant area to assess pollutant diffusion paths and serve as a decision-making basis for emergency response.

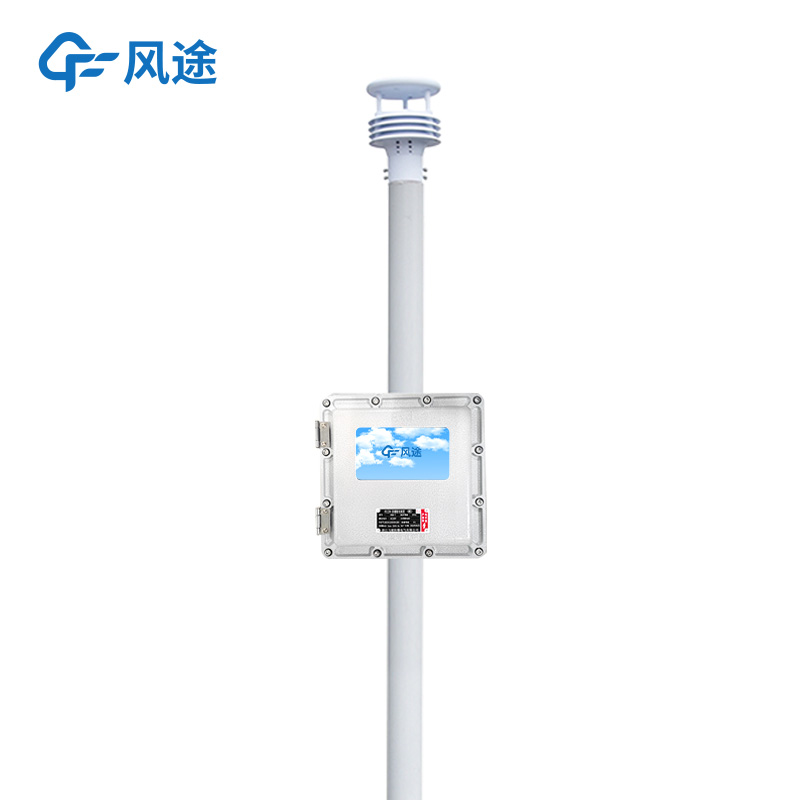

Therefore, an Industrial Weather Station is an industrial-grade environmental monitoring device specifically designed for the chemical industry. Its core function is to measure and record key meteorological elements in real-time, continuously, and accurately, primarily providing direct data support for safe production and environmental protection in the plant area.

The core monitored parameters typically include:

Wind Direction and Speed: These are the most important monitoring items. They are used to predict the diffusion direction and range of toxic, harmful, or flammable gas leaks and serve as key bases for initiating emergency evacuation and shutdown measures.

Temperature: Ambient temperature affects the rate of chemical reactions and the volatility of materials.

Atmospheric Humidity: Certain chemicals can react violently with water or deliquesce, making humidity an important safety and process parameter.

Atmospheric Pressure: It affects the boiling point of materials and the safety of sealed containers.

Modern Industrial Weather Stations have been deeply integrated into factory safety control systems. They are not just independent data display devices but also important data sources. Their measurement data is transmitted to the central control room in real-time and linked with gas leak detection and alarm systems, emergency response plan systems, etc. Once a specific dangerous gas leak is detected, combined with real-time wind direction and speed data, the system can immediately calculate the hazardous area and automatically issue evacuation alerts for downwind areas, thus forming a proactive safety protection system.

Handheld Weather Station FT-SQ8+ is a "meteorological monitoring expert" trusted by numerous users.Equipped with a 3.5-inch LCD screen, the FT-SQ8+ can clearly display a wealth of elements such as wind speed, wind direction, average wind speed, temperature, humidity, atmospher...

The Termite Monitoring System is a specialized device designed for the prevention and monitoring of termites in buildings, characterized by its installation requirement to be buried in the soil surrounding structures. This design concept is derived from the biological habits of termites and their in...

Gridization is a technical means that divides the geographical space into several regular or irregular grid units. Through independent monitoring, analysis, and management of each grid, it achieves refined management of the entire region. In the field of environmental monitoring, grid-based manageme...

Vehicle Weather Station is a professional mobile monitoring device based on the ultrasonic time-of-flight principle. It accurately calculates wind speed and direction by measuring the time difference of ultrasonic wave propagation, and integrates temperature, humidity, and pressure sensors to achieve real-time collection of multi-element meteorological data on a vehicle platform....